A heat press is one of the most essential tools in the printing and customization industry. It allows you to apply heat and pressure to transfer designs onto different materials like fabric, ceramic, and metal. Whether you are creating custom t-shirts, mugs, or tote bags, the heat press delivers professional-quality results that last long and look vibrant. Over the years, the popularity of this machine has increased among crafters, small business owners, and print shop professionals. It combines precision, durability, and consistency, making it ideal for producing high-quality prints that appeal to both hobbyists and entrepreneurs.

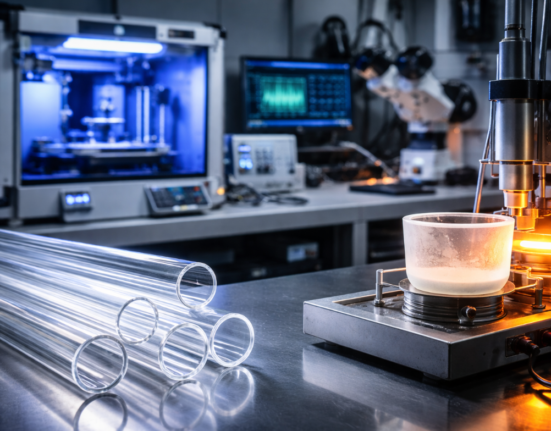

How a Heat Press Works

The concept behind a heat press is simple but powerful. The machine uses heat and pressure for a specific amount of time to transfer an image or design from a special paper or film onto a surface. Temperature control, even pressure distribution, and correct timing are crucial for achieving the perfect result. With digital technology advancing, many modern models come with smart controls and automatic pressure adjustments, simplifying the process for beginners while maintaining precision for experts.

Why a DTF Printer Complements a Heat Press

A dtf printer has revolutionized how people create transfers for their heat press projects. DTF stands for Direct to Film, and it works by printing designs directly onto a special film using vibrant inks. These designs are then coated with adhesive powder and cured before being pressed onto a garment. The dtf printer provides a more flexible printing option since it works on various fabrics, including cotton, polyester, and blends. Unlike traditional vinyl transfers that may crack or peel over time, DTF prints maintain their quality even after multiple washes, making them perfect for long-lasting custom apparel.

Combining Heat Press with DTF Printing

When a heat press and dtf printer are used together, they create endless opportunities for personalized design. First, the dtf printer creates a detailed, colorful image on film. Then, the heat press transfers that design onto the desired surface using high heat and even pressure. This combination is favored in small printing businesses because it ensures vibrant prints and efficient production. The setup is simple, allowing users to produce customized apparel, tote bags, or promotional items without needing large-scale industrial machines.

Benefits of Using a Heat Press

The most significant advantage of a heat press is its ability to deliver professional-quality results. It provides precise temperature and pressure control, ensuring that the transferred design adheres properly to the surface. Unlike traditional irons, the heat press covers the entire design area evenly, preventing hot spots or weak adhesion. It also allows users to experiment with different transfer types like sublimation, DTF, and heat transfer vinyl. For entrepreneurs, this means expanding services and creating multiple product lines with minimal investment.

The Role of DTF Technology in Modern Printing

A dtf printer enhances flexibility and color accuracy in custom printing. It allows high-definition images to be printed directly onto a film, which can later be transferred onto various materials using a heat press. This method is efficient for both small-scale and bulk production. One of its biggest advantages is that it removes the need for cutting or weeding designs, unlike vinyl. It also ensures that colors remain vibrant after several washes. The DTf printer has become a go-to solution for creative professionals who want to deliver high-quality prints quickly and efficiently.

Choosing the Right Equipment

Selecting the right heat press depends on your printing goals. For hobbyists or beginners, a small clamshell model works well. For professionals, swing-away or auto-opening models are more suitable due to their precision and speed. Meanwhile, when investing in a DTG printer, it’s essential to consider print quality, ink compatibility, and maintenance needs. Combining a durable heat press with a high-quality DTF printer creates a professional setup that guarantees exceptional prints every time.

Common Challenges and Solutions

Even though using a heat press is relatively simple, achieving consistent results takes practice. Common challenges include improper temperature settings, uneven pressure, or incomplete transfers. The solution lies in understanding the material you are working with and adjusting the settings accordingly. The same applies to a dtf printer, where proper curing and powder application are key to getting durable results. Regular maintenance and following manufacturer guidelines ensure long-lasting performance from both machines.

FAQs

Q. What can I create using a heat press?

A heat press can be used to make t-shirts, mugs, mousepads, tote bags, and more. It works on a variety of surfaces and materials, allowing for endless creativity.

Q. How does a DTF printer differ from traditional printing methods?

A DTF printer prints directly onto film instead of fabric. The design is then transferred using a heat press, which provides better color quality, durability, and flexibility compared to other methods.

Q. Is a heat press suitable for beginners?

Yes, many models are beginner-friendly with adjustable settings and digital displays. Even if you have no experience, you can quickly learn how to create professional designs with a bit of practice.

Q. Can I use the same heat press for different transfer types?

Absolutely. A heat press can handle sublimation, vinyl, and DTF transfers as long as the correct settings are used for each material. This makes it a versatile tool for any printing business.

Q. How long do DTF prints last on garments?

When done correctly with the right DTF printer and heat press settings, DTF prints can last through hundreds of washes without fading or cracking, maintaining their original look and feel.

Conclusion

The combination of a heat press and a DTF printer has completely transformed the printing and customization world. These tools offer unmatched precision, creativity, and flexibility, making them ideal for both personal projects and commercial production. A heat press ensures that your designs are permanently embedded with vibrant color and strong adhesion, while the DTF printer brings your ideas to life on film with detailed accuracy. Together, they allow users to explore an endless range of products, from apparel to accessories, without needing a large workspace or heavy investment. Whether you’re an artist, entrepreneur, or hobbyist, mastering these tools will help you produce professional-grade results every time, setting your creations apart in today’s competitive market.

Visit: Pure Magazine