Nahttypen are rarely discussed outside sewing circles. Yet they determine whether a garment lasts five washes or five years. They influence how fabric moves, how stress is distributed, and how the wearer experiences comfort. In practical terms, nahttypen are structural engineering decisions disguised as stitching.

Most online explanations reduce nahttypen to simple definitions: plain seam, French seam, overlock seam. But that surface-level approach misses the real question. Why does one seam hold under stress while another fails? Why does the same fabric behave differently depending on seam construction? And why are nahttypen more relevant in 2026 than ever before?

This article answers those questions in depth.

Why Nahttypen Matters More in 2026

The textile industry has evolved dramatically. Fabrics are no longer limited to stable woven cotton. Today’s garments often combine elastane blends, recycled synthetics, technical performance fibers, and lightweight sustainable materials. Each of these behaves differently under tension, friction, and repeated washing.

At the same time, consumers expect durability. Fast fashion fatigue has shifted attention toward repairability and longevity. When a garment fails, it is often not the fabric that gives way first. It is the seam.

Nahttypen, therefore sit at the intersection of engineering, sustainability, and design. Choosing the correct seam type is no longer just a craft decision. It is a functional and environmental one.

Understanding Nahttypen as Structural Systems

To understand nahttypen properly, we need to move beyond naming them and instead examine what they do mechanically.

Every seam must handle force. That force can be vertical tension from body movement, horizontal pulling from tight fits, rotational stress from twisting, or repeated micro-movements from daily wear. When force is applied, it travels through the fabric and concentrates at stitch perforations. If the seam construction cannot distribute that force evenly, tearing occurs.

Different nahttypen distribute stress differently. Some concentrate tension along a single stitch line. Others spread it across multiple layers. Some allow elasticity. Others restrict it deliberately for stability.

This mechanical perspective changes how we think about seam choice.

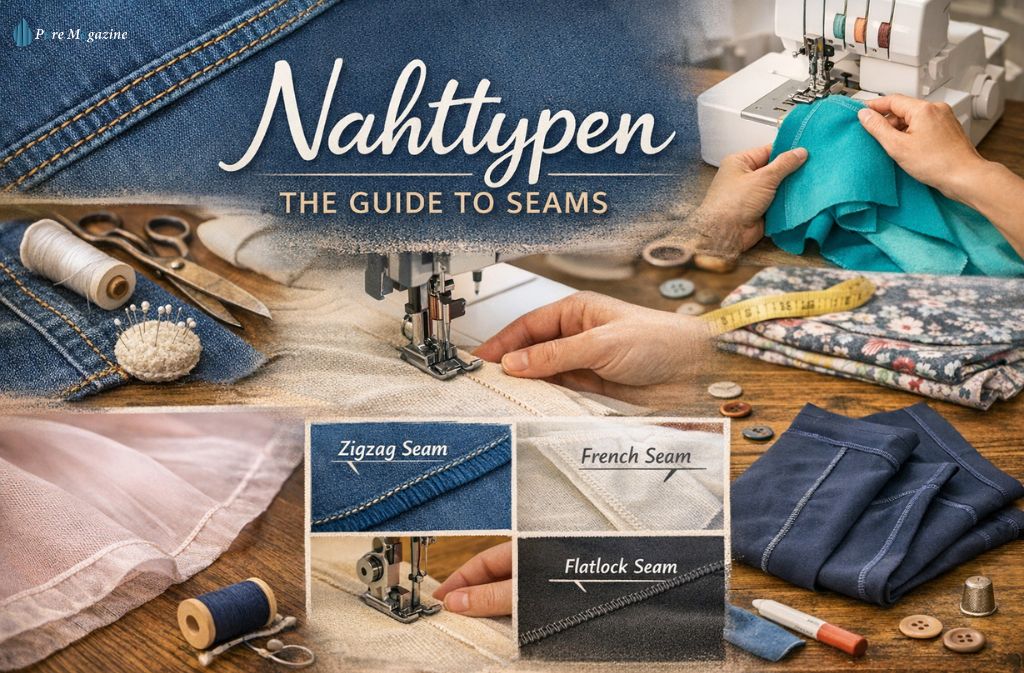

Core Nahttypen and Their Functional Logic

The straight seam, often considered the foundation of garment construction, is structurally simple. Two pieces of fabric are placed right sides together and stitched along a single line. This construction is efficient and versatile, but it concentrates tension along one row of stitches. In woven fabrics that do not stretch, this is often sufficient. In stretch fabrics, however, the straight seam may break under repeated movement because it lacks elasticity.

French Seam

The French seam takes a different approach. Enclosing raw edges within a second stitching line, it protects delicate fabrics from fraying. Mechanically, it does not dramatically increase tensile strength, but it increases durability in lightweight textiles by preventing fiber unraveling. It is particularly effective in sheer fabrics where interior finish matters both visually and structurally.

Flat-felled Seam

The flat-felled seam represents a more engineered solution. Frequently used in denim and workwear, it folds seam allowances and secures them with an additional line of stitching. This layered construction distributes force across multiple stitch rows and fabric layers. The result is high resistance to tearing and excellent performance under strain. When examining jeans’ inseams or shoulder seams in heavy garments, this nahttypen choice is rarely accidental.

Overlock Seam

Overlock seams function differently. Created with a serger machine, they bind edges while joining fabric simultaneously. Their key advantage lies in elasticity. The looping thread structure allows stretch fabrics to expand without snapping the seam. However, while flexible, overlock seams may not withstand extreme longitudinal tension without reinforcement.

Flatlock Seams

Flatlock seams, common in performance wear, prioritize comfort. Instead of stacking fabric layers, they create a flat connection that minimizes friction against the skin. From a mechanical standpoint, they maintain elasticity while reducing bulk. For athletes or active wearers, this difference is tangible.

Each of these nahttypen reflects a structural philosophy rather than just a sewing method.

A Brief Comparison of Nahttypen

| Nahttypen Type | Strength Level | Elasticity | Best Application |

|---|---|---|---|

| Straight Seam | Moderate | Low | Woven garments |

| French Seam | Moderate | Low | Lightweight fabrics |

| Flat-Felled Seam | Very High | Low | Denim, workwear |

| Overlock Seam | Moderate | High | Knits, stretchwear |

| Flatlock Seam | Moderate | Very High | Athletic apparel |

While this table simplifies differences, real-world decisions depend on fabric behavior and stress zones within the garment.

Also Check: Rise of Vertabrae Clothing: Streetwear’s Bold New Wave

The Science Behind Seam Failure

When seams fail, the cause is often misunderstood. Many assume poor thread quality is responsible. In reality, seam failure typically stems from a mismatch between fabric elasticity and seam structure.

Short stitch lengths increase strength but also perforate fabric more densely, which can weaken certain materials. Long stitch lengths allow flexibility but reduce holding power. Thread tension influences how evenly stress is distributed along the seam line. Even seam allowance width plays a role; too narrow, and the fabric can pull free. Too wide, and the seam becomes bulky.

In industrial garment testing, tensile strength machines apply a controlled pulling force until the seam fails. Often, the break occurs not at the thread itself, but where the needle perforations weaken the textile structure.

Understanding this interplay is essential when selecting nahttypen for modern fabrics.

Common Misconceptions About Nahttypen

One persistent misconception is that overlock seams are universally sufficient. While they work well for stretch fabrics, they may not be appropriate for load-bearing seams such as shoulders in heavy garments. Another misunderstanding is that adding more stitches automatically increases durability. Excessively tight stitching can compromise fabric integrity.

Some view flat-felled seams as purely decorative because of their visible topstitching. In reality, their strength lies in layered reinforcement. Others assume that any seam can work with any fabric. This assumption often leads to premature garment failure.

Nahttypen must align with textile physics.

Practical Application: Choosing the Right Nahttypen

Choosing correctly requires situational thinking. Consider a lightweight summer blouse made from viscose. The fabric drapes softly and may fray easily. A French seam not only improves the interior finish but also protects delicate fibers. Now compare that to denim jeans. The seam must withstand continuous friction and pulling. A flat-felled seam distributes that stress effectively and prevents unraveling.

In athletic leggings made from elastane blends, movement defines performance. Overlock seams maintain elasticity, while flatlock seams reduce chafing during extended activity. Each scenario demonstrates how nahttypen are responses to functional demands.

When selecting a seam, evaluate fabric composition, expected stress zones, stretch behavior, and desired lifespan. Seam choice should be deliberate, not habitual.

Limitations of Different Nahttypen

No seam type is universally ideal. Straight seams lack elasticity. French seams create bulk in thick fabrics. Flat-felled seams require precision and time, which may not suit rapid production. Overlock seams can weaken under heavy weight-bearing conditions.

Professional sewing involves balancing these trade-offs thoughtfully.

Also Read: Upgrade Your Wardrobe Effortlessly with Essentials Clothing Staples

Nahttypen and Sustainability in 2026

Sustainability discussions often focus on fabric sourcing. Yet seam construction directly affects garment longevity. A poorly constructed seam reduces usable life, increasing waste. A well-designed seam supports repair, alteration, and extended wear.

In a circular fashion economy, durable nahttypen are essential. Repair-friendly seams allow consumers to maintain garments rather than discard them. In this way, seam engineering contributes quietly but significantly to environmental responsibility.

FAQs

Q. Which nahttypen provide the highest durability?

Flat-felled seams are among the strongest due to layered construction and reinforced stitching lines.

Q. Are nahttypen different for woven and knit fabrics?

Yes. Woven fabrics generally use stable seams like straight or flat-felled seams, while knit fabrics require elastic constructions such as overlock or flatlock seams.

Q. Why do seams sometimes fail before the fabric tears?

Because stitch perforations concentrate stress, especially if the seam type and fabric elasticity are mismatched.

Q. Can multiple nahttypen be combined in one garment?

Absolutely. High-quality garments often use different seam types depending on stress zones and functional requirements.

Q. Are decorative seams structurally important?

Often yes. Many visible seam styles also serve reinforcement purposes.

Conclusion: Nahttypen Are Engineering Decisions in Disguise

Nahttypen are not minor technicalities. They determine structural performance, comfort, longevity, and sustainability. The difference between a garment that endures and one that fails often lies in seam construction rather than fabric choice.

The most appropriate seam is not the most complex one. It is the one aligned with fabric behavior and functional demand.

Understand nahttypen deeply, and every garment becomes stronger by design.

That is not simply sewing knowledge.

It is structural thinking.

Related: Futuristic Fashion vs. Organic Clothing: A Style Showdown